Quality Die Sets and Crimping Applicators in

Clinton Township, MI

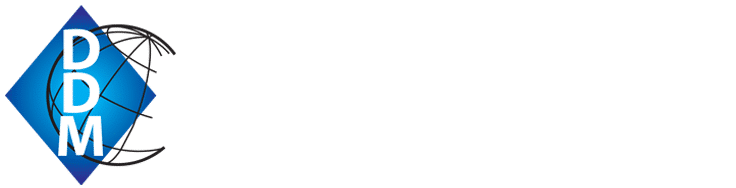

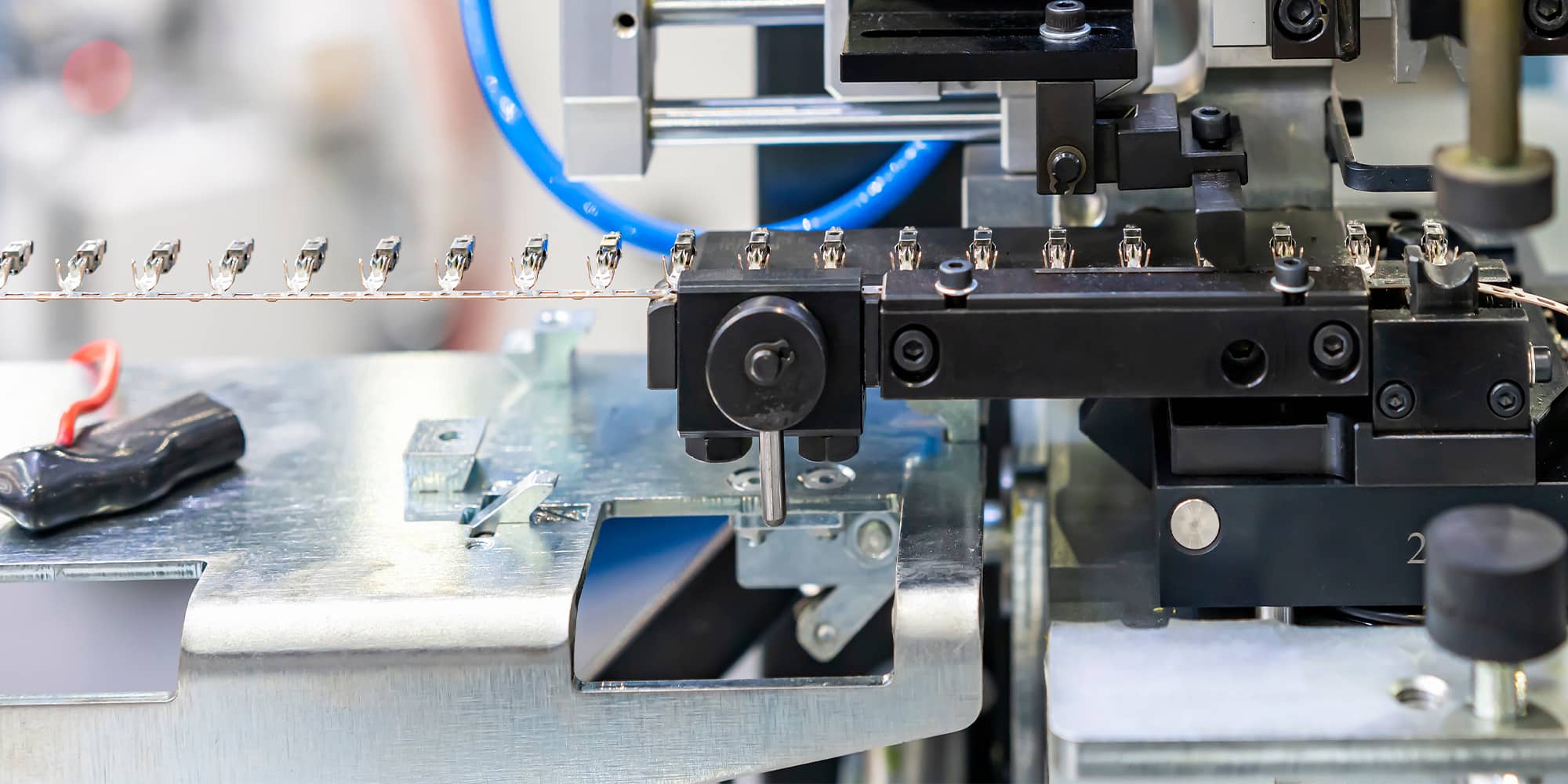

Our die sets and crimping applicators are the gold standard in the industry. Meticulous attention to detail, rigorous testing, and proven manufacturing processes result in tools that increase your operational efficiency, reduce machine downtime, and improve your output quality.

Beyond the tooling benefits, partnering with Diamond Die means that you are part of a business relationship built on trust and reliability. We aim to fulfill your tooling requirements and foster a partnership for continuous improvement and operational excellence.

Unparalleled Benefits of Our Die Sets and Crimping Applicators

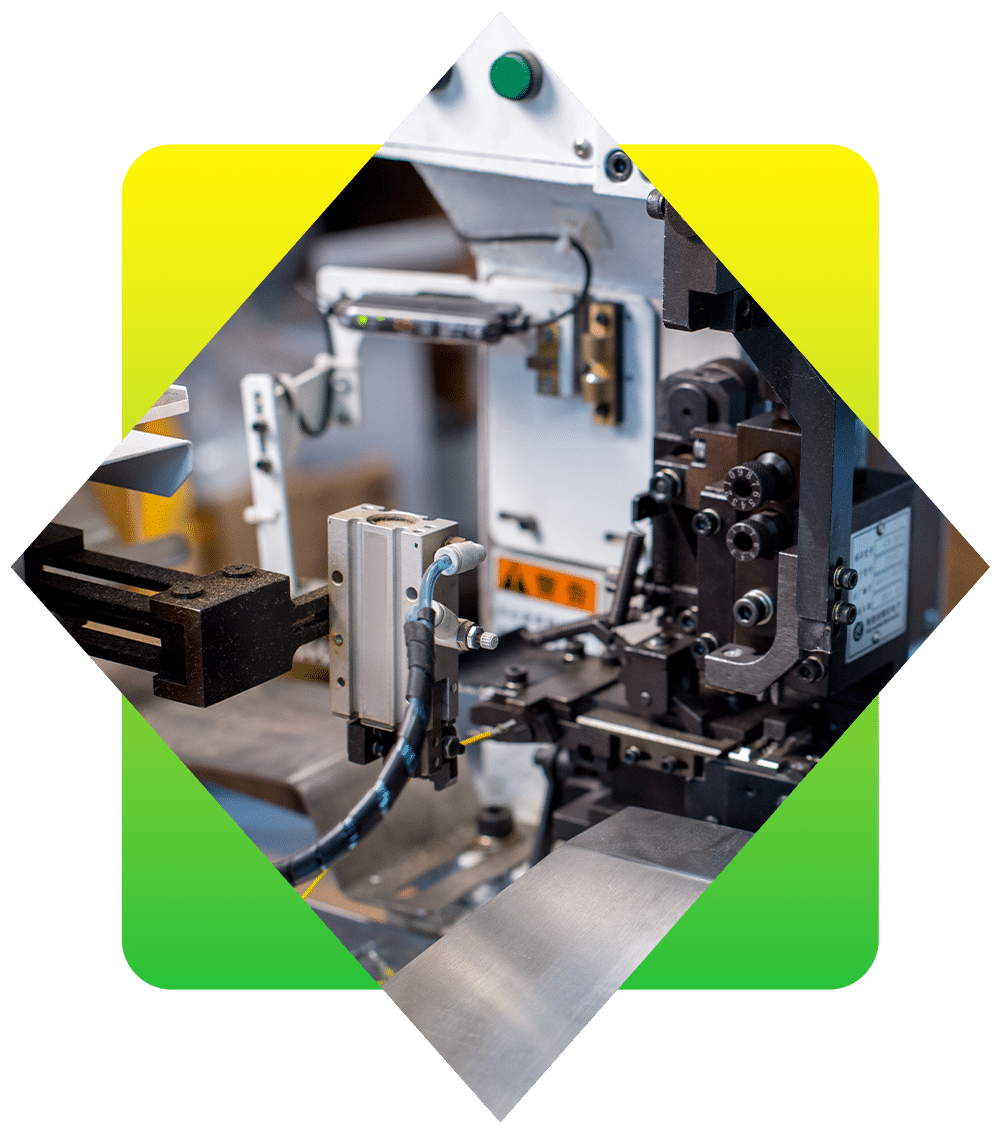

Diamond Die offers three specialized applicators that set a new industry standard. With a focus on performance and reliability, these applicators are built to accommodate various wire sizes and terminal types, serving many industries, from home appliances to the automotive industry.

Every Diamond Die applicator is meticulously engineered to meet the demands of intensive manufacturing processes. Our applicators provide remarkable consistency, ensuring each crimp meets the exact specifications you require, enhancing the overall quality of your production.

The Unique Benefits of Our Crimping Applicators

Unlock Your Manufacturing Potential With Diamond Die Tools and Crimp Applicators

Don’t let subpar tools hold you back! Choose our cutting-edge die tools and crimping applicators to unlock your manufacturing potential. Experience the elevated precision, durability, and efficiency standards that have satisfied countless industry leaders. Optimize your production process and secure your competitive edge by investing in trusted tools. Contact us today to get started!